A magnetic flow meter (also called an electromagnetic flow meter) is a device that measures the flow of a liquid by using a magnetic field. It works by applying a magnetic field to a pipe that carries the liquid and measuring the voltage that is induced across the liquid by its movement. The voltage is proportional to the flow rate of the liquid perpendicular to the magnetic field.

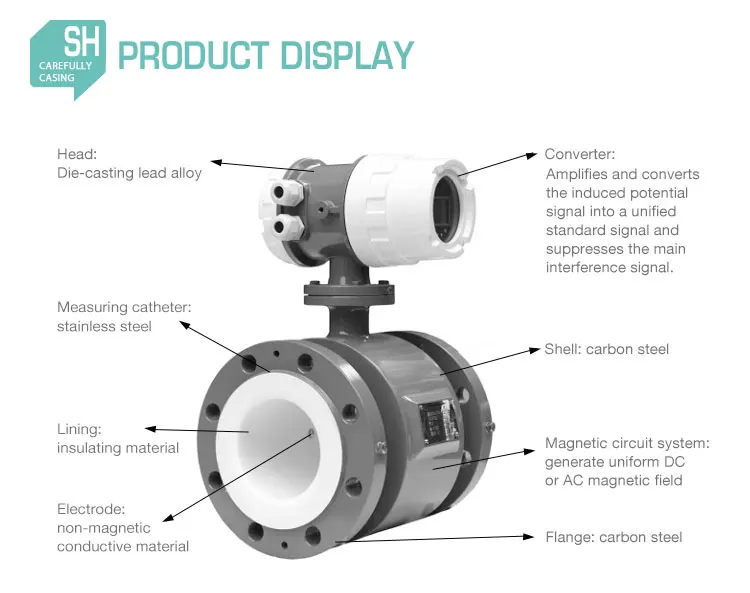

A magnetic flow meter consists of two main parts: a sensor and a transmitter. The sensor is placed in line with the pipe and has electrodes that detect the voltage generated by the liquid. The transmitter converts the voltage into a flow measurement and sends it to a control system.

Magnetic flow meters are suitable for measuring liquids that are electrically conductive, such as water, wastewater, chemicals, pulp, and slurry. They have no moving parts, which means they are durable and require less maintenance. They also have high accuracy over a wide range of flows.

Overview

The intelligent electromagnetic flow meter is a kind of flow meter with high accuracy and reliability.

It is used to measure the volume flow of liquid and slurry in closed pipelines and is widely used in power, petroleum, chemical, coal, metallurgy, minerals, paper making, water supply and drainage, food, medicine, and other industries.

Scope of Application

Chinese and English display intelligent converter adopts a 16-bit embedded microprocessor. Full digital processing, with two-way flow measurement function, instantaneous flow, and positive and reverse accumulation and difference accumulation, is used to measure the volume of conductive media such as fresh water, sewage, acid, alkali, salt solution, or liquid-solid two-phase fluid flow.

Features

Flow measurement is not affected by changes in fluid density, viscosity, temperature, pressure, and conductivity.

There are no obstructing flow parts in the measuring tube, no pressure loss, and low requirements for the straight pipe section.

The converter adopts LCD backlight display, which can make the degree easier under direct sunlight or in the darkroom.

Set parameters by touching the infrared ray button, which can be safely set without opening the cover of the converter in harsh environments.

The flow meter is a two-way measurement system with three integrators: forward total, reverse total, and difference total; it can display forward and reverse flow and has multiple outputs: current, pulse, digital Communication, and HART.

The converter has self-diagnostic alarm output, no-load detection alarm output, flow upper and lower limit alarm output, batch processing control, and other functions.

Not only can be used for general process detection, but also suitable for the measurement of the ore pulp, paper pulp, and paste liquid.

The high-pressure electromagnetic flowmeter sensor adopts PFA meshing lining technology, which is resistant to high pressure and negative pressure and is specially used in petrochemical and mineral industries.

Explosion-proof instruments can be used in corresponding explosion-proof places.

Product Parameters

Nominal diameter: DN3-DN3000

Nominal pressure: 0.6-4.0MPA (special pressure can be customized)

Accuracy: ± 0.5% of the indicated value

Lining material: polyurethane rubber/chloroprene rubber/polytetrafluoroethylene/silicone lining

Electrode form: standard type/scraper type / replaceable type

Electrode material: 316L / Haz alloy B / Haz alloy C / titanium/tantalum/platinum

Medium temperature:

Integrated-type: -20 ℃ ~ + 70 ℃

Split type:

1. Polyurethane rubber, neoprene, PTFE, silicon-fluorine lining

2. PTFE lining / PFA lining / F46 lining

Ambient temperature: -20 ℃ ~ + 60 ℃

Ambient humidity: 5 ~ 85% RH (relative humidity)

Dielectric conductivity: ≥20

Measuring range: 1500: 1 Flow setting<15m / s

Structure: integrated / split/immersion/explosion proof

Protection grade: IP65 / IP67 / IP68 optional

Explosion-proof grade: Exmd II CT4

Product standard: JB / T9248-1999 electromagnetic flowmeter

Features

1. Clear LCD display screen, display instantaneous flow and cumulative flow respectively;

2. Advanced excitation technology, brief excitation circuit with stability and reliability;

3. Pioneering fuzzy algorithm technology applies to the measurement of electromagnetic flowmeters with the performance of artificial intelligence;

4. Empty and full pipe measurement technique to avoid false alarms;

5. With low conductivity measurement function;

6. Prompt response design for high resistance, undistorted collection of weak signals, and prompt reaction for flow change, the range rate can achieve 100:1;

7. Various optional output communication interfaces.

Technical Performance Parameters

Main Power | AC220V 50Hz /DC24V/3.6V | |

Power consumption | <15W(Supporting power consumption with sensors) | |

Display and buttons | Display in Chinese and English can display instantaneous flow, cumulative flow, and alarm display (excitation open circuit alarm, empty pipe alarm, flow limit alarm). 4 membrane touch switches for data sets | |

Counter | Forward total, reverse total | |

Output Signal | Analog output | Two-way, fully isolated 0~10mA/4~20mA |

Load resistance: 0 ~ 1.5kΩ when 0 ~ 10mA; 0 ~ 750Ω when 4 ~ 20mA | ||

Frequency output | Forward and reverse flow output, the upper limit of output frequency can be set within 1 ~ 5000Hz. Open collector bidirectional output of transistor with photoelectric isolation. The external power supply is not greater than 35V, and the maximum current of the collector when conducting is 50mA. | |

Alarm Output | Two open-collector alarm outputs with photoelectric isolation transistors. The external power supply is not greater than 35V, and the maximum current of the collector when it is turned on is 250mA. Alarm status: fluid empty pipe, excitation disconnection, flow overrun. | |

Pulse output | Forward and reverse flow output, the upper limit of output pulse can reach 5000CP / S. The pulse equivalent is 0.0001 ~ 1.0m³ / P. The pulse width is automatically set to 20ms or square wave. Open collector output of transistor with photoelectric isolation. External power supply is not greater than 35V, the maximum current of the collector when conducting is 50mA | |

Matching accuracy | ± 0.5% of market value, optional ± 0.2% or 1% of indicated value | |

Damping time constant | Continuous variable from 0 ~ 100s (90%) time grading optional | |

communication | Optional RS232C or RS485 serial communication interface, HART communication protocol, with anti-lightning protection | |

Loss of power | The internal design of the instrument has a power-off clock, which can store 16 drop-out records (10 years) | |

Protection level | IP65 | |

Explosion-proof mark | Exs[ia]ia||cT5 | |

Lining Material

Material | Main Performance |

Polyurethane rubber | 1. Very good wear resistance coal slurry, mud, ore slurry, etc. 2. Not resistant to acid, alkaline, and other corrosive or high-temperature media 3. There must be no negative pressure in the pipeline |

Neoprene | 1. Very good elasticity and wear resistance 2. Capable of measuring domestic sewage, non-corrosive industrial sewage PH value: in the range of 6/7/8, temperature below 80 ℃ liquid 3. There must be no negative pressure in the pipeline |

Teflon F-4 PTFE | 1. Boiling-resistant hydrochloric acid, sulfuric acid, nitric acid, aqua regia, concentrated alkali, and various organic solutions 2. Strong abrasion resistance and poor bonding performance 3. There must be no negative pressure in the pipeline |

Perchloroethylene propylene F-46(PTFE) | 1. On the basis of all functions of PTFE, the temperature of the non-corrosive liquid can be increased within 140 degrees 2. Not resistant to fuming nitric acid, butyl lithium 3. There must be no negative pressure in the pipeline |

Silicone fluoride lining | Temperature resistance: 70 degrees, mainly high temperature. It can be used to measure hot water in heating systems and is not resistant to corrosion. |

Electromagnetic Flowmeter Electrode Material

Material | Material Corrosion Performance |

316L electrode | Application: domestic/industrial water, sewage PH value: within 6/7/8 Not applicable: corrosive media such as hydrofluoric acid / hydrochloric acid/chlorine/iodine |

HB | Application: certain concentrations of hydrofluoric acid and other oxidizing acids and non-oxidizing hydrochloric acid, alkali solution with a concentration of not less than 70% sodium hydroxide. PH value: within 5/6/7/8 Not applicable: Oxidizing acids such as nitric acid |

HC | Application: corrosion resistance to oxidizing salts or environments containing other oxidants, especially to seawater. PH value is within 6/7/8/9 Not applicable: hydrochloric acid, dilute sulfuric acid, phosphoric acid, and other reducing acids and chlorides |

Ti | Application: chloride, hypochlorite, seawater, oxidizing acid. PH value: within the range of 6/7/8/9/10 Not applicable: hydrochloric acid, sulfuric acid, and other acidic media |

Ta | Application: concentrated hydrochloric acid, nitric acid, sulfuric acid, and other acid liquids, including boiling hydrochloric acid and nitric acid. PH value: within 3/4/5/6 Not applicable: alkali, hydrofluoric acid, fuming sulfuric acid |

Pt | Various acids, bases, and salts. Not included: Royal Water |

Selecting Flowmeter Type

Integral type and split type

Both integral type and split type have their own advantages, and basic principals for selection are as follows: the split type is usually used in situations inconvenient for one-site maintenance and numerical reading when debugging is difficult or the flowmeter is often immersed in water and with other functions, It is also used in poor application situations, such as high temperature fluid, a position with vibration source and explosive environment. In most cases, both the integral type and the split type can meet use requirements.

General type and explosion-proof type

Users shall confirm to select a general type or an explosion-proof type according to application environment of the flowmeter.

The diameter of the sensor and that of technological pipeline.

Generally, It is suggested not to select reducing pipe for the sake of convenient installation, provided that the use flow in the flowmeter pipe shall be within the range of 0.3m/s~10m/s. This kind of selection is usually applicable to a newly-designed project for whitch current work situation is not only considered when choosing a flow speed, but also a situation of running at full load of the device in the future shall also be considered. For the relationships among the flux, velocity and diameter, see curve graph. However, sometimes we also choose a sensor with a different diameter with the connectetechnological pipeline diameter, for example:

1. The flow speed in the pipeline is low and the process flow is stable,in order to meet the demand of instrument to flow range, to improve flow speed at local of the flowmeter, select a sensor with smaller diameter than the diameter of the technological pipeline, and additionally connect a reducing pipe at front and rear part of the sensor.

2. In terms of large diameter electromagnetic flowmeter, the diameter is larger,the price is higher, as for the situations with low flow speed in the pipeline and stable technological parameter, small diameter flowmeter maybe chosen, this not only runs the flowmeter under good working state, but also reduces investment cost at the same time.

Selection of grounding ring material

Grounding ring material can be the same as the electrode material, generally material with the same corrosion resistance as the pipeline material is selectable.

Selection of lining material

Lining material should be selected according to the type and working temperature of measured fluid. PFA is a fluorinated plastic, has good corrosion resistance to strong acid, strong alkali, at the same time has good high temperature resistance, does not deform at high temperature. Insulation resistance is not reduced.99.9%high purity alumina is used for making ceramic lining so that the instrument can measure the flow with high precision. In comparison with traditional high polymer material, ceramics can not create high temperature, high pressure deformation, and have good wear resistance.

Selection of protection grade

Degrees of protection provided by enclosure are as follows according to GB4208-84, International Electrotechnical Commission(IEC) standards(IEC529-76);

IP65 is an anti-spray type, i.e.a water faucet is allowed to spray water to the instrument in any directio. The pressure of spray water is 30KPa(0.3bar). Water yield is 12.5 liters/minute. The distance between spray water and the instrument is 3m, IP67 is an anti-immersing type, i.e.theinstrument can be totally immersed in the water in a short time. The highest point is 150cm below the water during test. The duration time is 30minIP68 is a submerged type, which can work in thewater for a long period. The maximum depth immersed is negotiated by manufacturers and users.

The selection principles of protection grade are determined by the above mentioned requirements and actual working conditions of the instrument. If the instrument is installed underground and often immersed under water, it"s suggested to select IP68. If the instrument is installedabove the ground and the environment is not wet, choose IP65.

Because the voltage of sensing signals of the electromagnetic flowmeter is small, it is easily affected by the noise.

The reference potential must bethe same as the measured fluid. So the reference potential (terminal potential) of the sensor, the reference potentials of coverter and amplifer are the same as the measured fluid. And the fluid potential should be the same as the ground potential. The electromagnetic flowmeter is equipped with a grounding ring, which plays a role in establishment of fluid ground by contacting the fluid, at the same time, protecting the lining.

Daily Maintance

Make the direct inspection for the electromagnetic flow meters, check the surrounding,clean the dust and dirt, make sure no water inside and others, and check the line is connected, check if have the electromagnetic equipment or the new electric wire across the meters. If the medium easy pollute the electrode or deposit, scaling on the inside of tube, it should been clean on time.

Notice

1. It should be avoid the electromagnetic equipment to avoid the sensor send the signal.

2. It should be install in dry and ventilate place, avoid the sunshine and rain, the temperature should be -20~+60℃, relative humidity should be less 85%. If the humidity more bigger, it should be dampproof to avoid the humidity into the line box.

3. When install the electromagnetic flow meters, it should be guarantee the surrounding have enough space to install and repair.

Requirement for the Surrounding

1. The electromagnetic flow meters should not install the place where the temperature change a lot, or the place been high-temperature radiation.

2. The installation place for the electromagnetic flow meters more better if inside of house, if must be install outside, it should be avoid the rain and heavy water, and sunshine, it should have damppoof and sunscreen.

3. The electromagnetic flow meters should be avoid to install the place where is have corrosivity air, if can’t avoid the corrosivity air, it should have ventilate solution.

4. When install the electromagnetic flow meters, it should be guarantee the surrounding have enough space to install and repair.

5. The install place for the electromagnetic flow meters should be avoid the magnetic field and heavy vibration, if the pipeline have the heavy vibration, it request install the support equipment to steady the meters.

Hot Tags: dn50 electromagnetic flow meter mini seawater tap water liquid control intelligent magnetic electromagnetic flowmeter, manufacturers, wholesale, pricelist, quotation